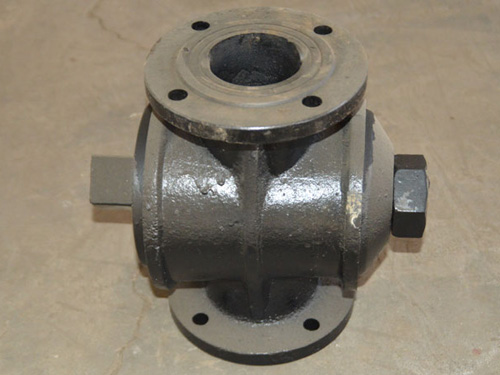

The coke oven gas insulation plug is a three-way plug valve,with a"T"shaped hole on the plug core and three corresponding holes on the valve body.The plug core is closely matched with the valve body.

The coke oven gas insulation plug is a three-way plug valve,with a"T"shaped hole on the plug core and three corresponding holes on the valve body.The plug core is closely matched with the valve body.

The installation of the coke oven heating gas exchange plug core has directionality,and after maintenance,it should be installed according to the direction marked on the plug core.The direction marking on the plug core is very simple,which is a"T"shaped shallow groove carved at the end of the plug core and painted.Because the plug core can be installed from any angle,and the identification will also rotate with the working state,when cleaning,maintenance,and installation,when the identification is blurry or due to the negligence of the operator,it often leads to incorrect installation of the plug core,leading to gas leakage.If a small amount of gas leakage is found in time,it can be corrected in a timely manner;If not detected in a timely manner,it can cause fire and explosion in the basement.Through investigation,it was found that similar accidents have generally occurred in various coking plants.

The measures for preventing misinstallation of coke oven gas insulation cocks are simple to implement,easy to operate,low investment,and effective.They can not only be used for equipment transformation that has already been put into use,but also can be applied in the manufacturing and processing stage of cocks.

A coke oven equipment used to control the lean gas entering the exhaust gas exchange switch,especially a lean gas exchange cock with good sealing performance,energy conservation and emission reduction,and easy observation,including a plug shell,plug core,plug cover,moving rod,and spring.There are decarbonization holes on both the plug core and plug shell,and a cover plate is provided above the decarbonization hole of the plug shell.The oil grooves on the plug core and plug shell are both equipped with rounded corners,and the two ends of the plug shell are equipped with flanges to increase its strength.The large end of the plug core is equipped with reinforcing ribs in the same direction as the gas through-hole of the plug core.Compared with the existing technology,the beneficial effects of this utility model are:①increasing the tightness of the cock and reducing the leakage of lean gas;②Reduced the amount of lean coal gas discharged into the atmosphere through the flue,reduced air pollution,and saved energy;③Preventing corrosion of pipelines by condensate;④This facilitates workers to observe the position of the plug switch and improves work efficiency.

A simple and effective improvement measure for preventing misinstallation of gas exchange cocks is to process the working surface of the combination of the plug core and the square hole of the exchange wrench,install a positioning pin on the square head of the plug core,and process a positioning groove on the assembly surface of the square hole of the exchange wrench.By matching the positioning pin and groove,the assembly direction of the plug core and the exchange wrench is ensured,and the installation is correct.This measure solves the problem of misinstallation that traditional gas exchange cocks are prone to during cleaning and assembly,and can prevent gas leakage.It not only improves the efficiency of cleaning and assembly work.

Ordinary coking enterprises all have the problem of high energy consumption and heavy pollution.At th...

The cold coke discharge device is installed at the bottom of the dry quenching tank to discharge the ...

Half of the air pollution on the top of coking equipment accessories is caused by the escape of raw g...